|

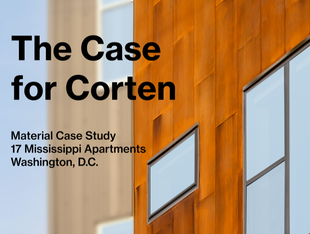

Attending architecture school in the mid-2000's, I was always enamored with the material Corten steel. Corten is a great material that has not only a nice warm hue and texture, but also is authentic - real metal that is really rusting. The sentimental architect in me lauds the poetry of the building's age being seen in the facade as it continuously rusts, like an active ruin of a bygone era. I know, I know - you didn't come here for that - but it does have a beautiful aesthetic that makes any building stand out in a crowded market. We believe that it should be used more often in our cities and especially on our affordable housing projects. We will use our recently completed project 17 Mississippi Apartments as a case study. Why Corten?COR-TEN (CORrosion resistance, TENsile strength) steel as it is officially referred to was a steel that was developed in the 1900's for outdoor applications, as the steel would form a natural protective coating (rust) as it is exposed to the elements. As the panels rust, a beautiful patina develops, starting at an orange color and ending at a brown color. This process can take up to ten years and is constantly changing day by day. The steel can be made into a variety of different forms and shapes - including flat sheets for cladding. The product has been used around the world on infrastructure, public art, and buildings both as roofing and cladding. There are many benefits in using Corten cladding on buildings, including:

Our Process17 Mississippi Apartments is a recently completed 41 unit affordable housing project that utilized Corten cladding. Below is our step-by-step process for success with Corten:

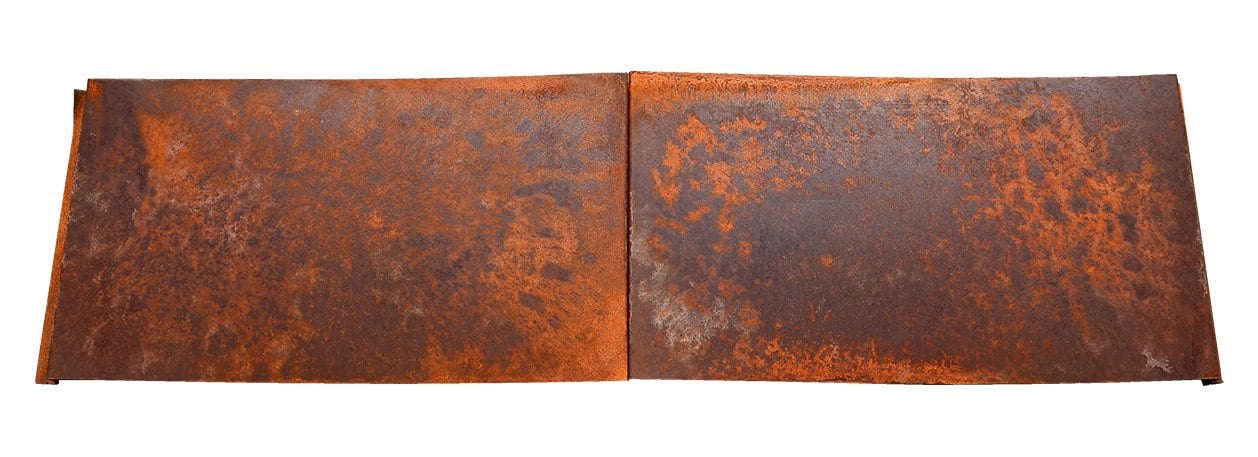

Design and PriceRustWall Concealed Fastener Panel The building had a number of units set aside for artists in the neighborhood, so we wanted to with a palette of unique and tactile building materials. We reviewed a few options, but came across the Rustwall product from Western Metal Roofing. The concealed fastener panel is easy to install and only needs a 1/2” z channel to work in a rain screen system. The astonishing thing was the price for the material - I recently re-checked this and the material is under $4 a sf. As we went through the pricing and value engineering process, we were able to keep the product in the budget. Mock-Up Wall TestingAs we discussed the material with the client, it came up that the client wanted the patina finish to not only be achieved by groundbreaking, but also for it to remain into perpetuity. The panel, when it arrives on site, is a battleship gray. Our renderings relied on the orange patina and the client expected this on day one. Luckily, there are rust accelerants to speed up the process, as well as rust coatings that would stop the process all together. Testing was performed on a mock-up wall prior to implementation on the building. We tested all sorts of application styles (brush, roller, spray etc…) and number of coatings. The rust accelerant was particularly impressive. In a matter of minutes, what would take a year to create magically appears in front of your eyes. The mock-up phase was necessary to get ownership buy-in and also for us to get the correct coloring for the building. We were now ready for the full order and install. Mock-Up wall prior to accelerant Mock-Up wall with one coating (left and two coatings (right) of rust accelerant InstallationAt 17 Mississippi, we used a vertical alignment for the panels and applied directly to the Zip sheathing backup. This allowed water to flow down the weather barrier without any pooling. We installed all panels without any coatings applied and then washed the panels with a hose to remove any oils or adhesives that may have been used during shipping. The client was a bit concerned about runoff staining, so we installed a 3” wide gravel strip on grade below the panel. This process was complete within a week and is not any different from a traditional cladding install.  Vertical panel install

Final ThoughtsThe pictures below speak for themselves - we achieved the proposed aesthetic and the building really pops. We are also proud to announce that a year after install the product is still in good condition and no staining/runoff is seen at any of the windows or at the ground. The panels even look better than they did a year ago. I also want to emphasize that the three coatings are not needed - this product could be installed and left to rust naturally over time. It is really up to the building owner’s preference. Although there is some extra care that is needed with this material, it is not overly expensive or hard to work with and maintain. This should open the door for more builders and designers to add a new look to their palette and further beautify our world in the housing they provide. 1 year later and no runoff staining seen

1 Comment

Soto's insight and expertise in the implementation of this project is admirable, and we're proud to have played a part in it. We at BROMOCO are thrilled to see our products, particularly XL-08 Rust Accelerant, ERW-BD Rust Neutralizer, and CT-7571 Rust Sealant, contributing to the success of this project. It's truly inspiring to witness how the innovative use of Corten steel not only adds a unique aesthetic appeal but also underscores the project's commitment to sustainability and durability. Congratulations on a job well done! 👏 👏 👏

Reply

Your comment will be posted after it is approved.

Leave a Reply. |

|

Soto Architecture & Urban Design is Registered as a Certified Business Enterprise (CBE) by The District of Columbia's Department of Small and Local Business Development (DCDSLBD) and as a Minority-Owned Business Enterprise by the Maryland Department of Transportation (MDOT). We are also a USGBC and Energy Star Partner.

Soto Architecture & Urban Design, pllc

1407 T Street NW Suite 200

Washington DC 20009

(202) 750-6717

Soto Architecture & Urban Design, pllc

1407 T Street NW Suite 200

Washington DC 20009

(202) 750-6717